thanks Dave, i try to do the best i can with what little i have to work with.

got more work done today.

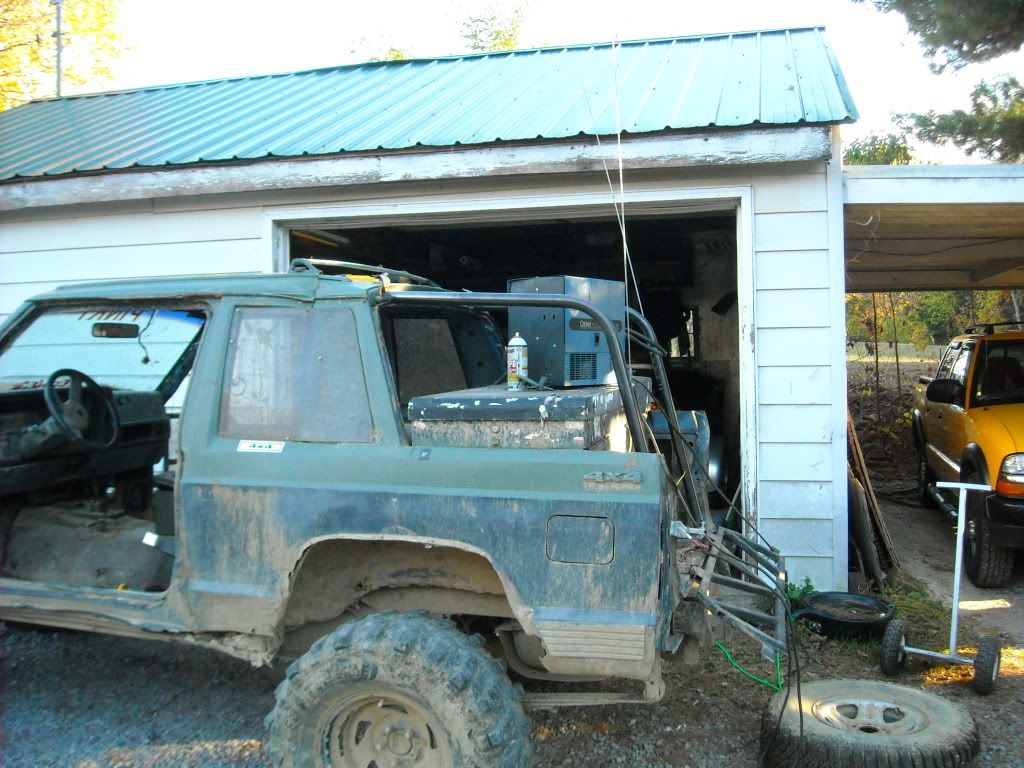

where it has been chopped, the section where the hatch used to sit is lower than the rest of the roof, so it had to be notched out for the tubes to slid through.

then floor plates were bent and welded in. due to the contour of the floor and my placement of the main hoop, the bottom of the rear support is litterally as far back as it could possibly have gotten. floor plates required two bends in them to get them to lay flat for a good welding surface. this was simply done via a BFH and a bench vise.

next i layed in the crossbar/belt bar

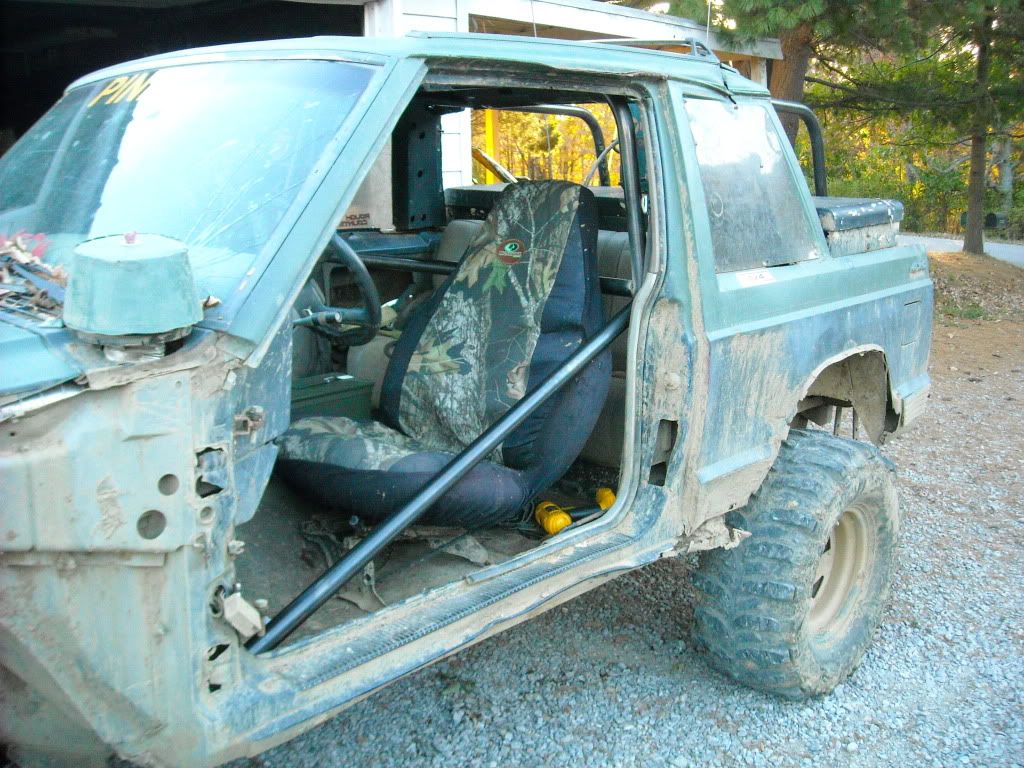

seat fitment is perfect. seat all the way back (where i drive as i am 6'2") the back lays nicely against the bar.

just for fun, i sat in the back seat to see how it was, and even as tall as i am, there is still room back there. not gonna lie it is tight, but for a shorter person it won't be to bad, and they can hold onto the bar if need be. the only issue i see is getting in, which will be a pain now with it. but thats their problem i know where i always sit :lol:

then dropped in a door bar just for an idea of how it will look. did not tack it in, as i need to install the Roof hoop and A-pillar bars first before i add them in.

it does lay across part of the seat, but sitting it it as i normally do, i did not even touch it. a larger built person might, but i did not. however, getting in with the bar in place does require a bit of skill.

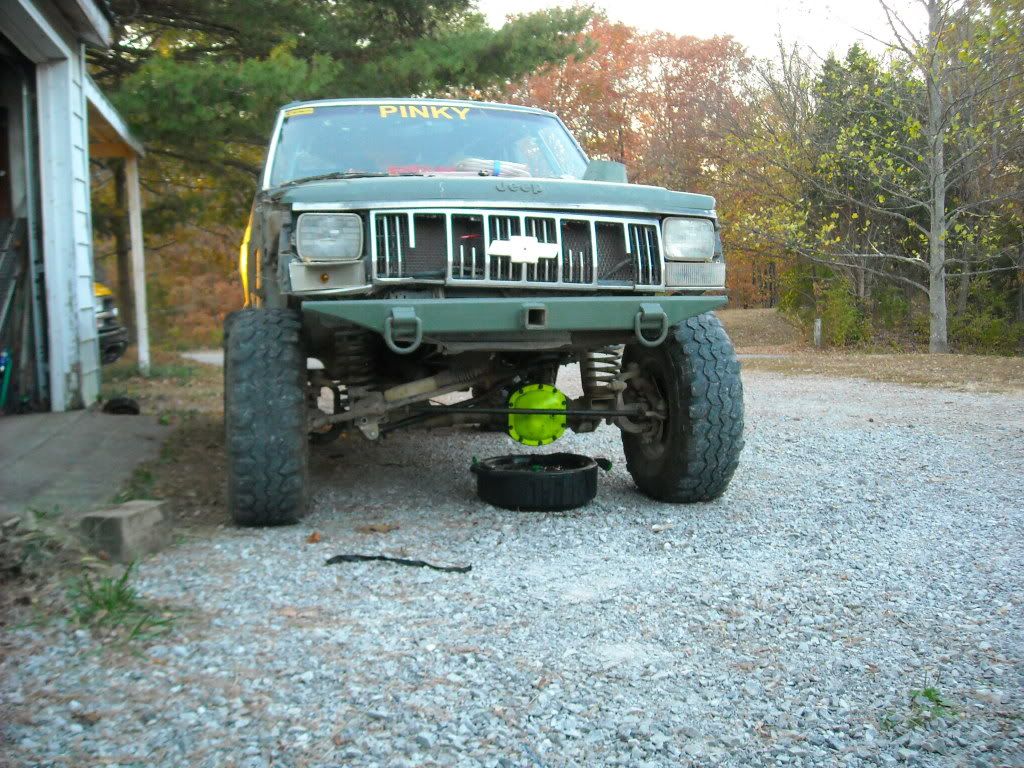

as i put it up for the night, i also created more work. Sheared Two bolt in my steering box jsut turning in my gravel driveway. so i gotta fix that before i can even more it again to begin to work once more.

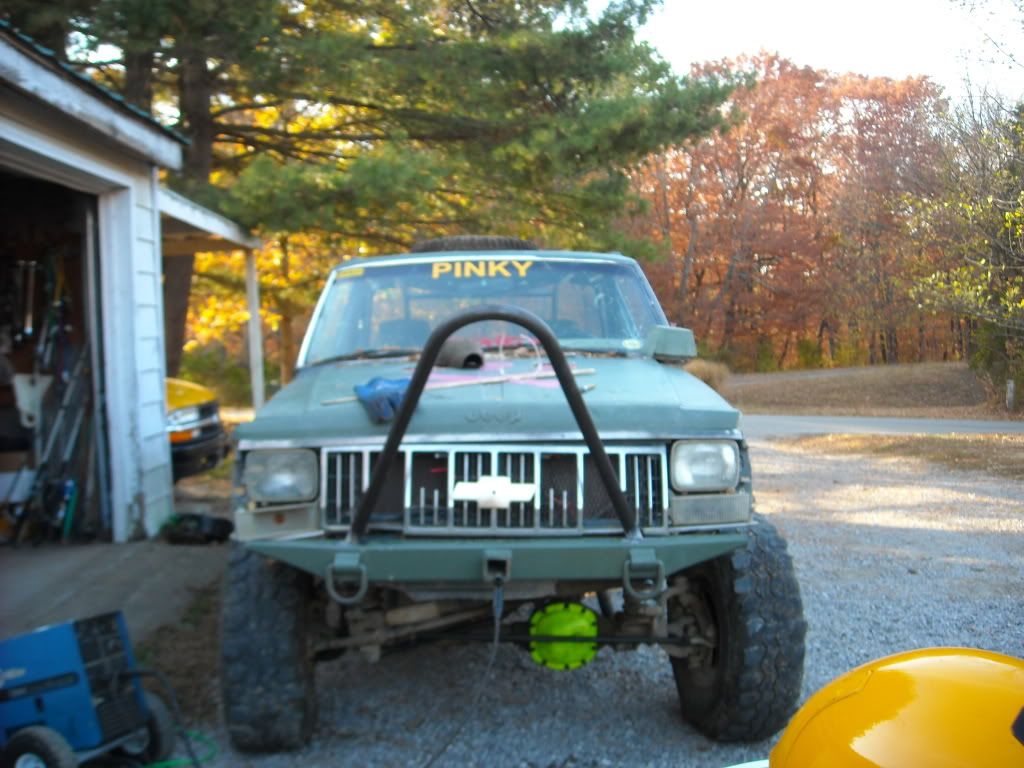

but after that is fixed, then the real fun starts tomorrow as i have to hack up the dash to install the A-pillar bars.